Metal

Metal

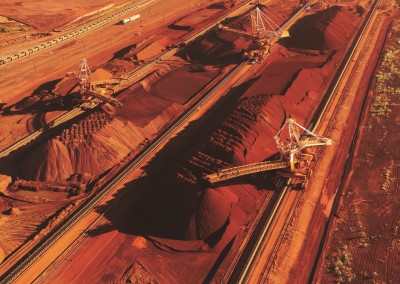

There are many different types of metals used in construction. How sustainable they are depends on your definition. If you take steel for example, it leaves scars in the Earth during its removal if it is not properly re-natured after. It emits large quantities of CO2 into the atmosphere during its manufacturing process, about 7% of the world total, but this could be reduced to some degree with more efficient equipment. An upside is that it can be recycled. So the sustainability of using steel depends on many factors, which is the same for every metal.

The higher the number the more sustainable and “green” the material

- Is there enough material so that we can continue to use it at the present rate… Is the present use sustainable? 32%

- Is the present use having little or no impact on the environment including destruction of habitat and CO2 release 14%

- Ability for the Material to be Harmlessly Returned to Nature 17%

Metal

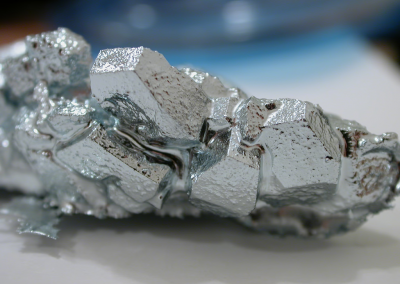

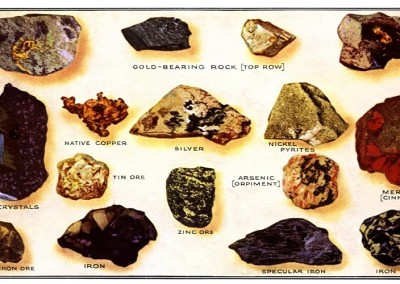

A metal is a material (an element, compound, or alloy) that is typically hard, opaque, shiny, and has good electrical and thermal conductivity. Metals are generally malleable — that is, they can be hammered or pressed permanently out of shape without breaking or cracking — as well as fusible (able to be fused or melted) and ductile (able to be drawn out into a thin wire). About 91 of the 118 elements in the periodic table are metals (some elements appear in both metallic and non-metallic forms).

Basalt

Basalt is a common extrusive igneous (volcanic) rock formed from the rapid cooling of basaltic lava exposed at or very near the surface of a planet or moon.

Basalt fiber is a material made from extremely fine fibers of basalt, which is composed of the minerals plagioclase, pyroxene, and olivine. It is similar to carbon fiber and fiberglass, having better physicomechanical properties than fiberglass, but being significantly cheaper than carbon fiber.

Basalt fiber is made from a single material, crushed basalt, from a carefully chosen quarry source and unlike other materials such as glass fiber, essentially no materials are added. The basalt is simply washed and then melted.

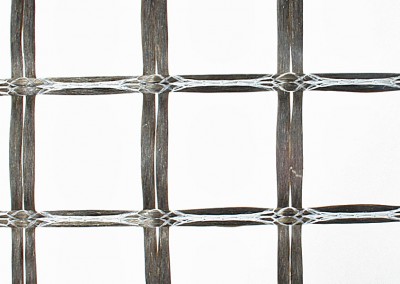

The manufacture of basalt fiber requires the melting of the quarried basalt rock at about 1,400 °C (2,550 °F). The molten rock is then extruded through small nozzles to produce continuous filaments of basalt fiber. There are three main manufacturing techniques, which are centrifugal-blowing, centrifugal-multiroll and die-blowing. The fibers typically have a filament diameter of between 9 and 13 µm which is far enough above the respiratory limit of 5 µm to make basalt fiber a suitable replacement for asbestos. They also have a high elastic modulus, resulting in excellent specific tenacity—3 times that of steel.

Basalt is 7 times lighter than steel and capability of using 30% less concrete when used as reinforcement, because it won’t rust and therefore doesn’t need to be as thick. Domes built with basalt can bare a weight of 400 pounds per square foot.

Dome Reinforced with Basalt Video

Click Image Below See More Building Materials and Their Sustainability